Did you know that the performance of your smartphone battery hinges on something as simple as the size of graphite flakes? In industries ranging from energy storage to heavy manufacturing, flake graphite is a powerhouse material—and its mesh size is the key to unlocking its potential. But what exactly does “mesh size” mean, and why does it matter? In this guide, we’ll break down everything you need to know about mesh sizes in flake graphite, from how they’re measured to how they shape real-world applications.

Momentum Minerals is here to simplify this critical concept, whether you’re sourcing graphite for batteries, lubricants, or refractories. Let’s dive in.

What Are Mesh Sizes in Flake Graphite?

Mesh size refers to the particle size of flake graphite, determined by the number of openings per linear inch in a screen or sieve. Think of it like a filter: a 50-mesh screen has 50 holes per inch, while a 200-mesh screen has 200 smaller ones. The larger the mesh number, the smaller the particle size—and vice versa.

- Larger Flakes: Denoted with a “+” (e.g., +50 mesh), these are coarser particles that don’t pass through the sieve.

- Finer Flakes: Marked with a “−” (e.g., -100 mesh), these are smaller particles that slip through.

This grading system helps classify graphite into categories like coarse (+50 to +80 mesh), medium (+80 to +100 mesh), and fine (-100 to -200 mesh), each suited to specific industrial needs.

How Mesh Sizes Are Measured

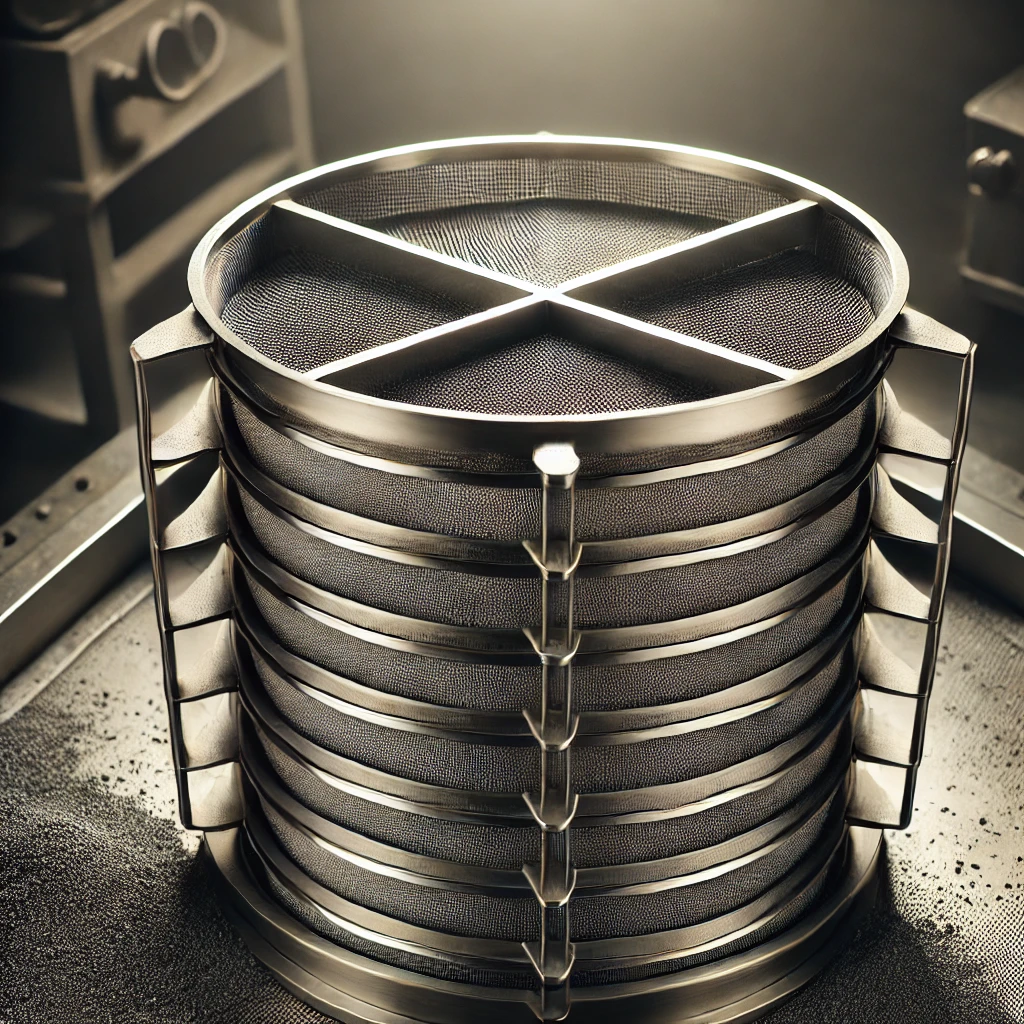

So, how do we get from raw graphite to a neatly labeled mesh size? The process starts with sieving, an industry-standard technique:

- Sieving: Flake graphite is poured onto a stack of sieves with progressively smaller openings (e.g., 50 mesh at the top, 200 mesh at the bottom). Mechanical vibration separates the particles, with larger flakes caught by coarser screens and finer ones filtering through.

- Analysis: The retained graphite on each sieve is weighed to determine the particle size distribution.

For precision in high-tech applications like lithium-ion batteries, some labs use advanced methods like laser diffraction, which measures particle sizes by how they scatter light. While sieving remains the backbone of graphite grading, these modern tools ensure tighter control for cutting-edge uses.

Why Mesh Sizes Matter

Mesh size isn’t just a number—it’s a performance driver. The size of graphite flakes directly impacts their behavior in applications:

- Batteries: Larger flakes (+50 to +80 mesh) enhance conductivity in lithium-ion battery anodes, improving charge efficiency and battery life. Finer flakes might clog the structure, reducing performance.

- Lubricants: Fine flakes (-100 to -200 mesh) excel in high-temperature environments, reducing friction smoothly in machinery or coatings.

- Refractories: Coarse flakes (+50 mesh) add strength and thermal resistance to crucibles and bricks used in steelmaking.

Choosing the wrong mesh size could mean a less efficient battery or a lubricant that fails under heat. That’s why understanding this property is critical for engineers and procurement teams alike.

Mesh Size Chart: A Quick Reference

Here’s a simplified guide to common mesh sizes and their typical particle ranges:

| Mesh Size | Particle Size (Microns) | Common Applications |

|---|---|---|

| +50 | >300 µm | Battery electrodes, refractories |

| +80 | 177–300 µm | Conductive coatings |

| -100 | <150 µm | Lubricants, fine coatings |

| -200 | <74 µm | Advanced composites, paints |

How to Choose the Right Mesh Size

Not sure which mesh size fits your needs? Here’s a quick checklist:

- Need Conductivity? Go for larger flakes like +80 mesh—perfect for batteries or conductive additives.

- Need Smoothness? Finer flakes (-200 mesh) shine in lubricants and coatings.

- Need Durability? Coarse +50 mesh bolsters refractories and structural materials.

Still unsure? Your supplier can tailor graphite to your specs—whether it’s a custom blend or a specific grade. At Momentum Minerals, we’re here to match you with the right solution.

Conclusion

From powering electric vehicles to keeping industrial machines running smoothly, flake graphite’s mesh size is a small detail with a big impact. By understanding how it’s measured and why it matters, you can make smarter choices for your projects. Ready to find the perfect flake graphite for your needs? Contact Momentum Minerals today for expert guidance and premium graphite solutions tailored to your industry.